Introduction

Material & Manufacturing

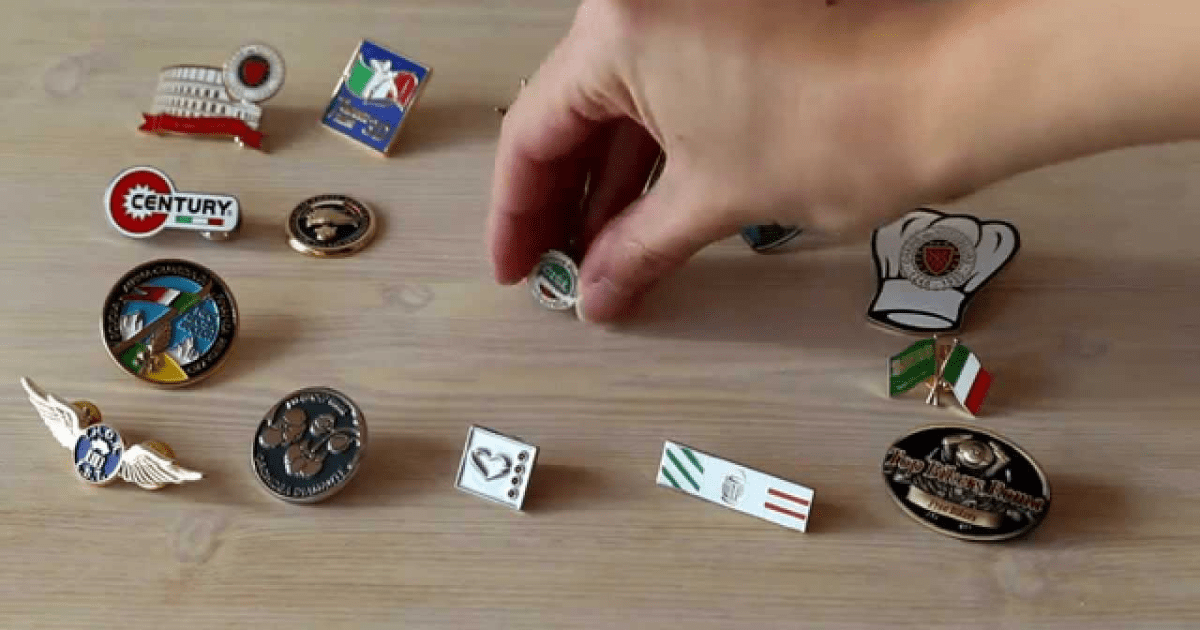

Custom lapel pins have become a trendy way to express identity, promote a brand, or celebrate a special cause. Whether used by companies for marketing, by individuals for fashion, or by organizations for recognition, lapel pins are small yet powerful tools of expression.

If you’re new to the world of custom lapel pins, this guide will walk you through everything you need to know—from design choices to material options and how they are made.

Designing Your Custom Lapel Pin,Material & Manufacturing

Designing a custom lapel pin starts with a concept. What message or theme do you want your pin to reflect? Whether it’s your brand logo, a catchy quote, or a symbolic graphic, the possibilities are endless.

When sketching your design, consider: size and shape (standard or custom cut) colors and finishes, and placement of text and logo. Material & Manufacturing

Tip: Use vector-based tools like Adobe Illustrator for high-resolution design files.

Choosing the Right Material

Lapel pins can be made from a variety of materials, and the choice you make will affect the look, feel, and cost of the final product. Some common types include:

Material & Manufacturing

Soft Enamel – Textured finish with vibrant colors

Hard Enamel – Smooth, polished look and highly durable

Die Struck – No color, just metallic imprint

Printed Pins – Good for complex or photo-based designs

The Manufacturing Process

Once your design and materials are chosen, it’s time to bring your pin to life. The manufacturing process generally involves:

Material & Manufacturing

1. Mold creation based on your design

2. Stamping or casting the metal

3. Enameling or printing

4. Polishing and plating

5. Attaching a backing (butterfly clutch, magnet, etc.)

Where to Order Custom Lapel Pins

There are many online companies that offer custom pin production with varying price ranges, order quantities, and turnaround times. A few popular platforms include:

Material & Manufacturing

Bonus: How to Use Lapel Pins Creatively

Custom pins aren’t just for lapels! Here are some unique ideas:

– Branded giveaways at events

– Employee recognition awards

– Wedding or party souvenirs

– Collector’s items and fandom merch

– Fundraising campaigns for social causes

Material & Manufacturing

Final Thoughts

Custom lapel pins are an excellent way to combine creativity and messaging in a compact form. With the right design, material, and manufacturer, your custom pin can become a lasting symbol of your brand, event, or passion.

Material & Manufacturing

As you dive into the world of custom pins, take your time with each step and don’t hesitate to seek inspiration. From small batches to mass production, lapel pins can help you stand out—literally and figuratively. Material & Manufacturing

| Aspect | Details | Impact on Pins |

|---|---|---|

| Material Options | Soft enamel, hard enamel, die-struck metal, printed, epoxy dome | Defines durability, texture, and final appearance |

| Metal Choices | Brass, copper, stainless steel, zinc alloy, iron | Influences weight, shine, and premium quality |

| Finishing Styles | Gold plating, silver plating, antique bronze, matte, glitter fill | Enhances aesthetic appeal and uniqueness |

| Manufacturing Steps | Design sketch → Mold creation → Stamping/casting → Coloring → Polishing → QC | Ensures precision, consistency, and flawless detail |

| Use Cases | Corporate branding, fashion accessories, charity awareness, event souvenirs | Strengthens identity, promotion, and style statement |